The pyrolyzer Spirajoule

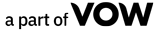

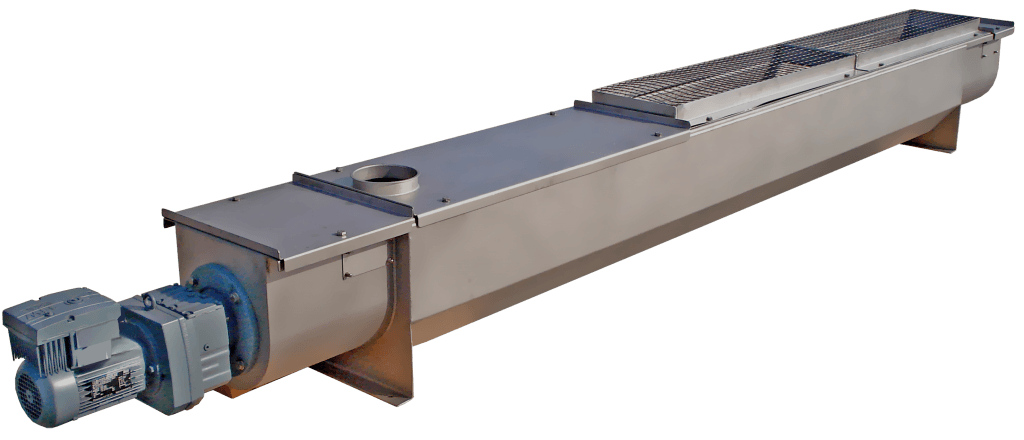

The Spirajoule® technology is an exclusive process for thermal treatment. It is designed with a worm screw conveyor heated by a low voltage current. The temperature of the screw is maintained due to the joule effect. Treated product temperature is precisely controlled by the regulation of screw temperature setting.

The residence time of treated material is regulated by setting of screw rotation speed. Spirajoule© technology is a simple and economical process with accurate and efficient operation for the heat treatment and valorisation of bulk products in wide range temperatures up to 800°C.

Spirajoule in Biogreen process

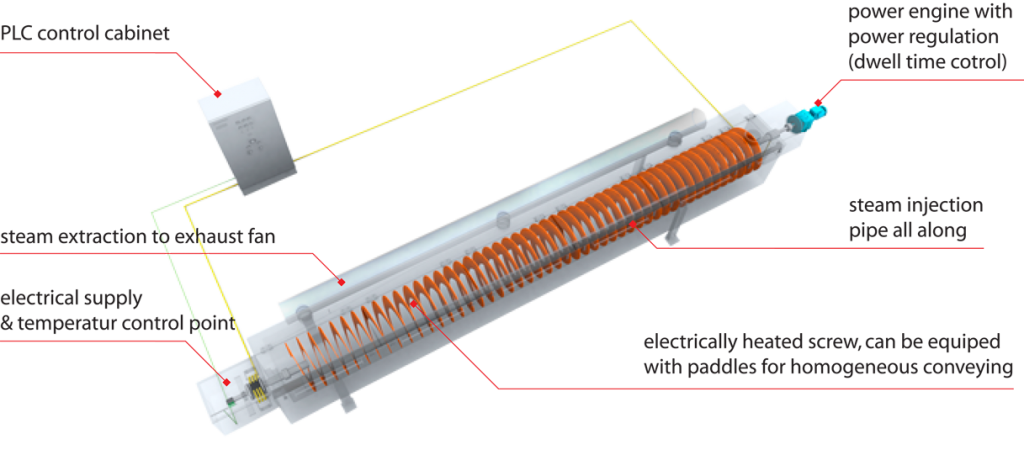

Spirajoule® constitutes a core part of Biogreen©, an innovative process for valorisation of bulk materials.

Processed bulk product, after entering the pyrolysis chamber is efficiently conveyed along the reactor and transformed by temperature in pyrolysis chamber. Conditions of treatment are continuously monitored and fully adaptable by operator. Thanks to the stable, electrical power supply, process conditions are precisely maintained along the pyrolysis chamber ensuring the uniform material conversion. Easy adjustment of Biogreen© operating parameters allows to setup optimum treatment conditions and meet the best performances for your individual product.

These features make Biogreen® a reliable solution that adapts to your process conditions and guarantees a constant quality of the production.

News

Biogreen is a thermochemical conversion process for converting biomass, waste and residues into high added value products.

Biogreen is a part of

Vow - vowasa.com

ETIA SAS

Carrefour Jean Monnet

BP 20101 60201, Compiègne

FRANCE

+33 3 44 86 44 20

NEWS

APPLICATIONS

© Copyright - ETIA SAS - a part of

Vow