Pyrolysis, torrefaction & gasification

Processes for biomass and waste

Read more-

Discover our applications

Top 20 Biogreen applications and business models for our pyrolysis process

Read more -

Pyrolysis of garden waste

Biogreen pyrolysis solution turn garden waste into useful bio-commodities and energy

Read more -

How to valorise garden waste?

In the times of climate emergency, money grow on trees

Read more -

Containerized pyrolysis unit

Easy to install pyrolysis plant for biomass and waste

Read more

Biogreen

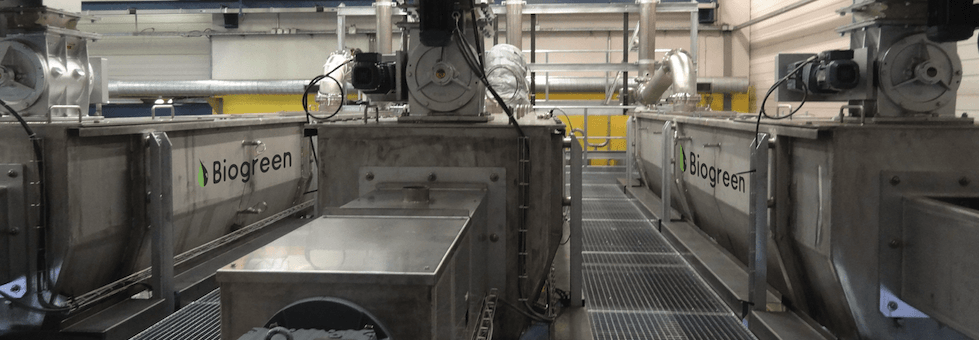

Flexible, modular system for industrial conversion of biomass and waste

Button

Waste to value

Converting waste to value with unique pyrolysis technology

Button

Biochar production

Sustainable product for a greener future in times of climate emergency

Button

Garden waste

Solution for turning waste into value for environment, community and society

Button

Pyrolysis, torrefaction process for biomass

Biogreen® is innovative, patented pyrolysis process operating since 2003. For more than a decade, our solution works for converting biomass, plastics, and waste into energy and useful products.

Biogreen© is a simple and flexible pyrolysis solution to produce biochar, oil, solid fuels and syngas from your biomass residues.

We provide plants for continuous treatment of sewage sludge that combine together the advantages of drying and pyrolysis processes.

Biogreen® pyrolysis process for rubber chips allows producing high energy syngas, oil and excellent quality of solid residue.

Discover our applications

With so much going on in the industry, it can be difficult catching up with all possibilities. Here’s our summary of Top 20 most exciting Biogreen applications and business models for our pyrolysis process.

Interested in pyrolysis?

Find out about our equipment by sending a request

High temperature pyrolysis

Biogreen® technology allows high temperature pyrolysis - also called gasification. High-temperature conversion leads to the maximum production of rich in energy gas which calorific values. After clean up process, generated gas can be applied as valuable fuel for the energy recovery.

We wish to share what makes us proud.

Join by subscribing our newsletter

Pyrolysis

Biogreen® pyrolysis process can be operated between 400°C up to high temperatures beyond 800°C. The controlled process provides quality solid products: biochar, recycled carbon black and many more. Pyrolysis oil finds interest as a liquid for chemical industries and refining substrate. Syngas is excellent fuel for energy production.

Turn garden waste into useful bio-commodities and energy.

Read more about

pyrolysis of garden waste

Pyrolysis, torrefaction & gasification

Biogreen© is a simple and flexible pyrolysis solution to produce biochar, oil, solid fuels and syngas from your biomass residues.

News

Learn about our newest applications and development of our company.

Biogreen is a thermochemical conversion process for converting biomass, waste and residues into high added value products.

Biogreen is a part of

Vow - vowasa.com

ETIA SAS

Carrefour Jean Monnet

BP 20101 60201, Compiègne

FRANCE

+33 3 44 86 44 20

NEWS

APPLICATIONS

© Copyright - ETIA SAS - a part of

Vow