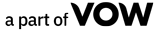

Biogreen pyrolysis technology - Thermochemical conversion of biomass and waste

Pyrolysis process in mobile, containerised and fixed equipment

Biogreen® is innovative, patented pyrolysis process operating since 2003. Since more than a decade, our solution works for converting biomass, plastics, and waste into energy and useful products.

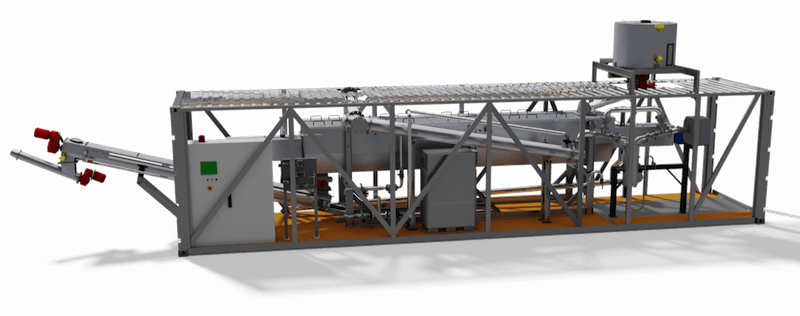

Biogreen pyrolysis process is based on electrically heated screw conveyor (Spirajoule®), designed for advanced thermal treatment in temperatures up to 800 degrees C and beyond. Processed product temperature is precisely controlled basing on the temperature settings. The dwell time of material inside Biogreen® reactor is regulated by screw rotation speed. Thermal conversion is performed in oxygen-free (pyrolysis) atmosphere in unique construction of equipment, which guarantees a constant quality of product obtained from the treatment.

What makes the Biogreen pyrolysis technology unique?

- Industrial pyrolysis operating for over a decade: first unit commissioned in 2003

- Continuous and fully automatic process of pyrolysis

- Highest quality of products

- Full and reliable control of treatment conditions

- Easy change of operating conditions

- Worldwide availability

- Variety of sizes and configurations

- Small footprint; « lean & mean » equipment

Biogreen is one of the leading pyrolysis processes in Europe

Protected by international patents, Biogreen® is an extremely versatile system that offers a wide range of possibilities for thermochemical conversion of biomass and waste into high added value materials and energy.

Biogreen is one of the leading pyrolysis processes in Europe, which demonstrated reliability and performance for over a decade of operation.

What are the applications of Biogreen pyrolysis process?

- biomass solid fuels production (torrefaction and carbonization process)

- municipal waste

- biochar (soil nutrients and enhancers) production

- conversion of sludge and industrial sludge into heat

What is the capacity of the Biogreen pyrolysis process?

Biogreen® module is designed to process up to 2,5 m3/h. Actual mass capacity is linked to the applied treatment time (« residence time ») of raw product and it’s apparent density (kg/m3). Residence time of material is set up in Biogreen® control panel and regulated by screw rotation speed. For obtaining higher capacities, Biogreen® pyrolysis units are placed in paralell.

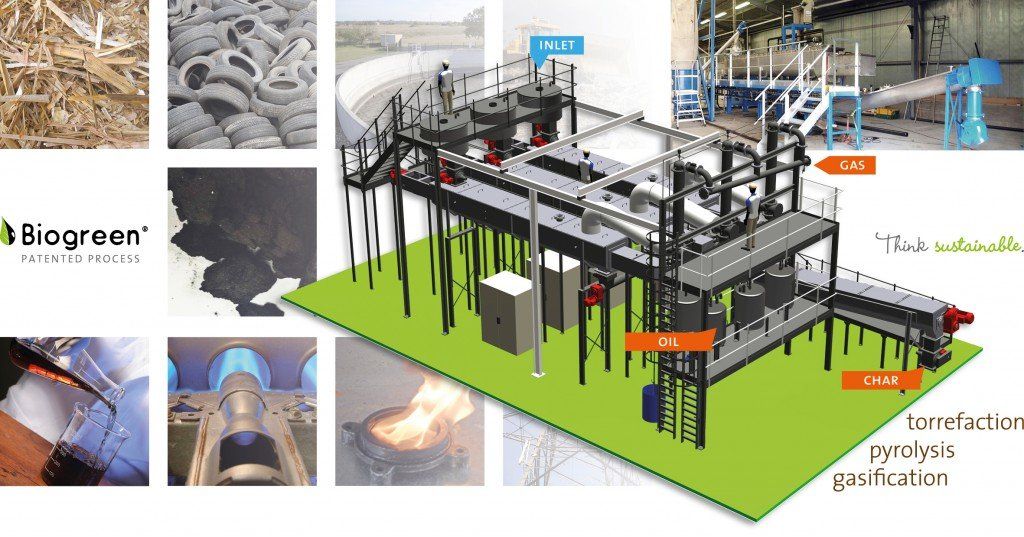

Containerised pyrolysis unit

Equipment can be delivered in containerised modules that allow to present a quick and ready to use version of the Biogreen® pyrolysis plant.

Unit can run in torrefaction, pyrolysis or high temperature pyrolysis mode to produce biochar, liquid products and syngas from many kinds of biomass waste from wood, crops or waste materials.

Easy to install pyrolysis plant for biomass and waste

- Compact and ready to use

- No installation, building or civil works

- Small, plug & play solution for processing your feedstock on site

What are the advantages of containerised pyrolysis plant?

The decision about containerisation is driven by multiple factors including project location, timing, permitting, operational schedule and local labour costs.

Containerized (CM) pyrolysis plants provide several advantages related to quick installation, facilitated transport and modular construction of the plant. This type of plant is suitable for fast, often temporary applications designed to be moved or rearranged after a time-period, shipped or stored in long-term. Because of it’s portable and standardized construction, BiogreenCM models are also recommended for limited space areas, projects constraining non-interference in local infrastructure, investments requiring no building work or remaining under particular law regulations.